PressureHab Pressurised Welding Habitat Systems

IECEx pressurised habitats and hot work control systems for hazardous areas

Hot work is a leading cause of industrial fires, consistently ranking in the top five causes of fires across all industries. Safespear aims to increase safety at workplaces by providing our technologically advanced products engineered to protect people working in hazardous environments.

Partnering with PressureHab Ltd, we are able to offer a market leading, 3rd party IEC60079-13 ATEX & IECEx certified, pressurised hot work habitat solution which provides our partners with enhanced safety while reducing cost and adding value in some of the most hazardous settings. Portable, modular, and highly fire-retardant, our habitats are utilised where hot work containment is required and desired to mitigate against the risks associated with hot work-related activities.

The PressureHab Hot Work Habitat System us compact & lightweight, and the innovation and certification surpasses all other habitat systems on the market.

Benefits of the PressureHab System.

Enhanced Safety

Fully IECEx 3rd party Certified Pressurised Room “Habitats” System

Engineered Control for the safe execution of hot work in an explosive atmosphere

Reusable and designed with hazardous areas in mind

Light, Portable and Fire Retardant

Maximises production uptime by allowing work to be done outside of shutdowns

Equipment.

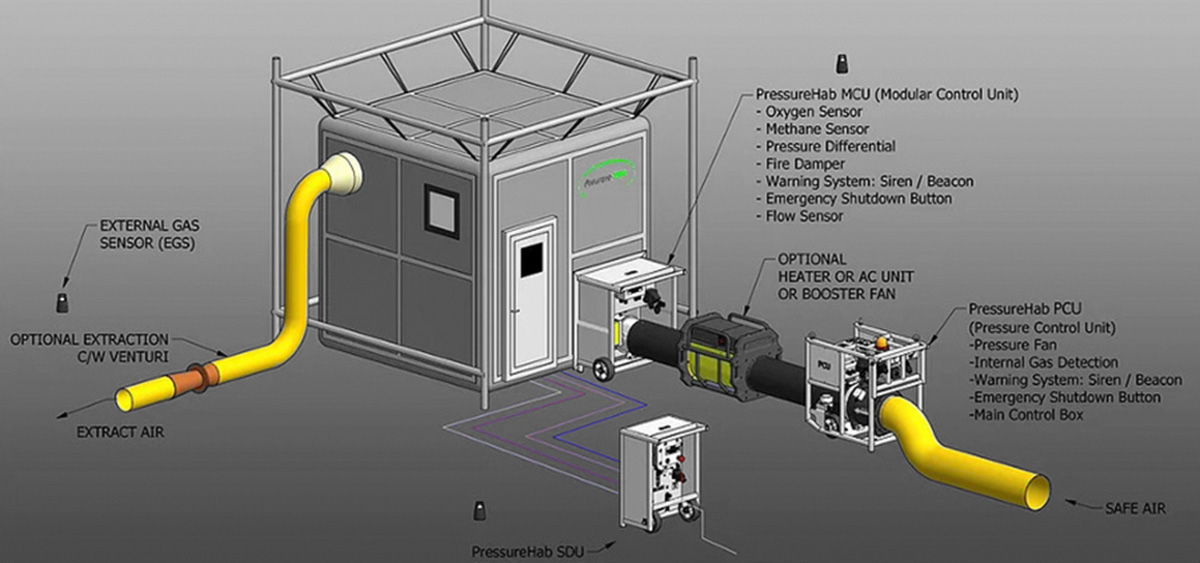

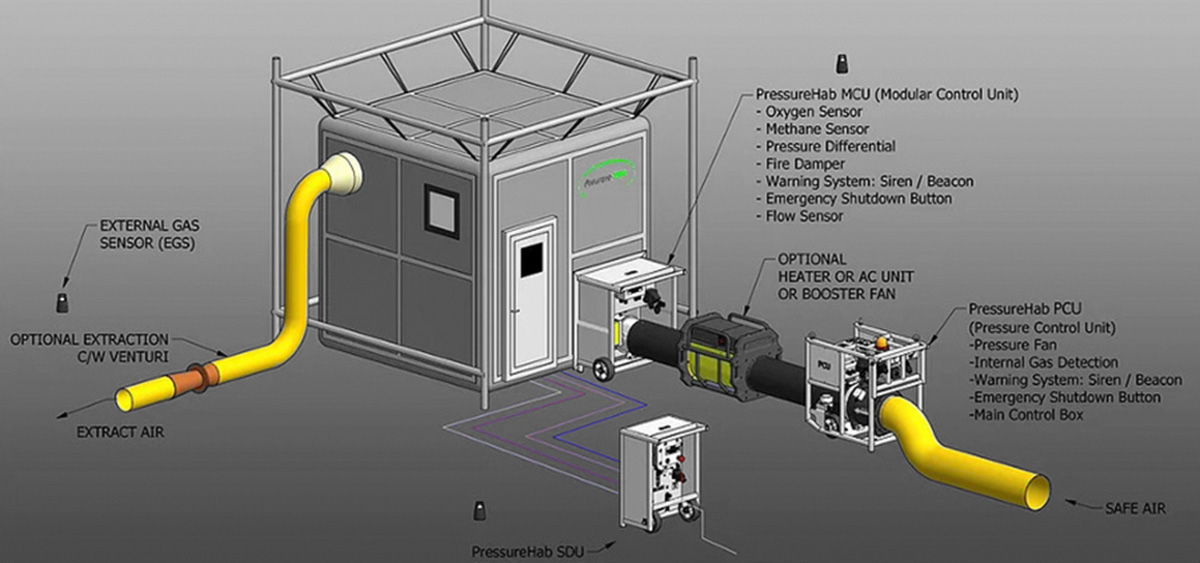

Safe-Stop Zone 1 Control System

The Safe-Stop Zone 1 control system is designed & 3rd party certified to IEC60079-13 standard for use in conjunction with our highly fire resistant welding habitats. Safe-Stop creates a safe overpressure environment and constantly monitors the pressure differential between the inside and outside of the PressureHab as well as Oxygen, Hydrogen Sulfide and Methane levels in the airflow and inside the PressureHab.

Upon detecting a loss of differential pressure, high or low oxygen levels, hazardous gases inside the PressureHab, the Safe-Stop System will automatically shut down the hot-work power supply to the PressureHab. Should any hazardous gases (such as H2S or CH4) be detected in the air-feed to the PressureHab, the Safe-Stop system will shut down both the power supply and the flow of air to the PressureHab

Safe-Stop Zone 2 Control System

PressureHab's economical Safe-Work Zone 2 control system provides a safe work environment within Zone 2 rated hazardous locations. Safe-Work Zone 2 control system is designed & 3rd party certified to IEC60079-13 standard for use in conjunction with our highly fire resistant welding habitats. Safe-Work creates a safe overpressure environment and constantly monitors the pressure differential between the inside and outside of the PressureHab as well as Oxygen, Hydrogen Sulphide and Methane levels in the airflow and inside the PressureHab.

Upon detecting a loss of differential pressure, high or low oxygen levels, hazardous gases inside the PressureHab, the Safe-Stop System will automatically give a visual & optical alarm (Beacon & Sounder) on the MCU and on the PCU. Should any hazardous gases (such as H2S or CH4) be detected in the air-feed to the PressureHab, the Safe-Stop system will shut down the flow of air to the PressureHab. This system is integrated into the PressureHab in the same way as the Zone 1 Safe-Stop system.